Plastics have become so common that it is hard to imagine a world without them. It is easy to understand why these versatile materials are used so widely. Plastics have properties that make them highly attractive to industrial designers: lightweight, inexpensive, airtight, durable, transparent or easily coloured, and moldable into virtually any shape imaginable.

The global production of plastics has grown exponentially from 2 million tonnes in 1950 to over 350 million tonnes in 2018, corresponding to almost 50 kg per human being each year. The plastics industry projects continued growth in global demand and are making major investments in new production facilities. According to one forecast, global production of plastics would exceed 1,800 million tonnes in 2050 — around half a kilo of plastics per person per day.

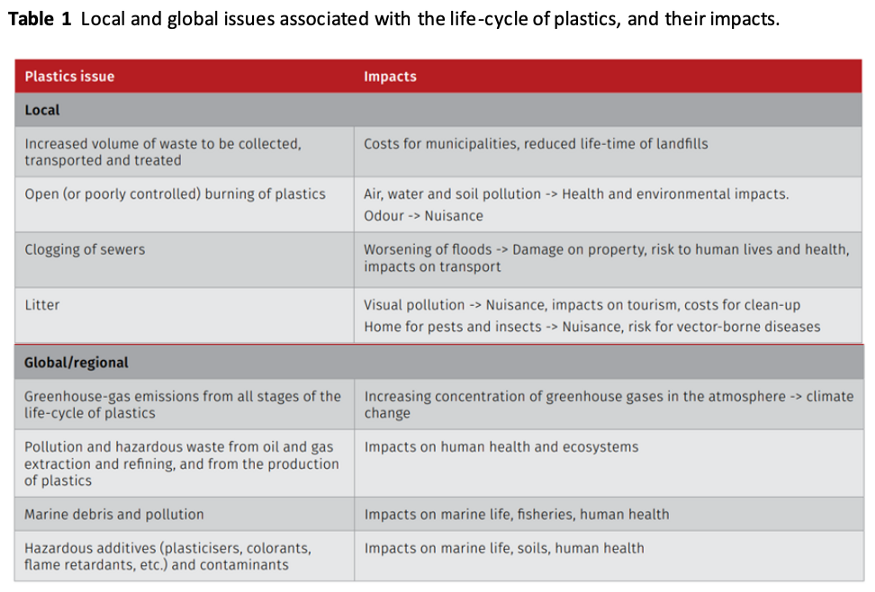

However, the high use of plastics is causing serious environmental impacts. Plastic pollution of the oceans, impacting marine life, has drawn significant attention in recent years. But the widespread use of plastics is problematic also for other reasons, including human health risks and climate impacts (Table 1). A growing movement is therefore questioning the use of plastics, in some cases even calling for a complete phase -out of plastics.

Given the environmental and other impacts of plastics, there are strong reasons to consider where and how these materials can be sustainably used. But a complete phase- out of plastics is not likely to be feasible and would not be desirable from a sustainability perspective either. After all, plastics have properties that in certain application make them hard to replace, such as for some types of medical equipment. There are also cases where the low weight of plastics can help achieve high energy efficiency, for example when used for vehicle parts. And while much plastics are currently used for making disposable items or short-lived products, some types of plastics are suitable for making durable goods.

We are thus likely to continue using plastics far into the future , but major changes can be expected in how we produce and use these materials.

A circular economy is often proposed as a solution to the sustainability issues related to plastics but the practical implications of this approach are not always clear. There are diverse interpretations of a circular economy and the concept is often misunderstood as mainly an approach to improved waste management and recycling. While improvements at the waste and recycling stages are much needed, this by itself will not lead to sustainable use of plastics. An undue emphasis on such downstream solutions ignores the wide range of changes that need to be made across product life-cycles.

It is impossible to predict in detail what a transition to sustainable use of plastics will look like, but, based on emerging trends and recent research, it is reasonable to expect the following to happen in the coming decade:

- Drastic reduction in single-use applications through the introduction of reuse systems and a shift to other materials (easily compostable materials or materials with low life-cycle climate impact).

- Shift away from fossil feedstocks (oil and natural gas) to increased use of renewable resources (bio-based plastics), including waste materials.

- A sharp drop in the use of plastics that are hard to recycle with high quality.

- Recycling processes that produce materials of sufficiently high-quality grades to substitute for virgin materials (closed-loop recycling).

- Introduction of new types of plastics, including those that are chemically designed for efficient recycling.

- Improved scientific understanding of how plastics break down under various conditions, including how engineered bacteria and enzymes can be used to speed up the degradation of waste plastics.

- Phase-out of plastic additives with known or suspected harmful properties.

- Improved methods for refurbishment and remanufacturing of plastic components, including by adding a new surface layer.

- Harmonised labelling of materials and consumer education.

- Improved standards and testing methods for biodegradability and compostability will bring increased clarity, reduce the risk for greenwashing, and make it easier to determine when such materials may be preferable.

- Packaging solutions that are adapted to local circumstances, including the actual capacity for safe waste management and effective recycling.

- Manufacturers will be expected or required to consider the entire life-cycle of their products to a much greater extent than currently and to take responsibility for managing sustainability issues across product life-cycles. This calls for improved communication and collaboration both upstream in value-chains and downstream in waste and recycling chains.

- Improved methods for monitoring and data analysis will make it easier to remove plastics that have ended up in the environment, including from the ocean.

A 4REVS intelligence case