Main Theme

Sub-theme: EEE, E-waste; electronics; eco-design; tech for good

Abstract

Today, more than 5 billion consumers interact with data every day. And by 2025, that number will grow to 6 billion or 75% of the world’s population. In 2022, the number of connected devices worldwide was 929 million; this number will keep growing.

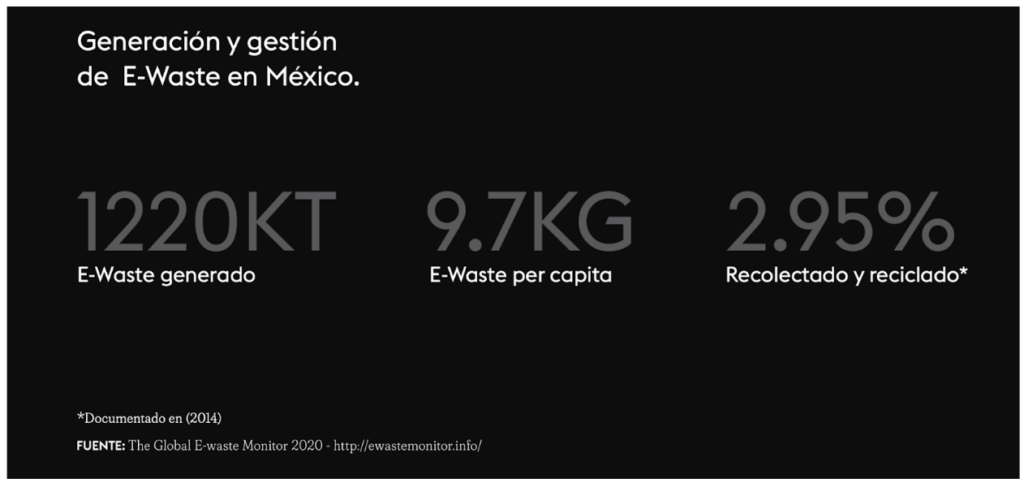

Digital transformation is directly linked to economic growth, and it also has a direct impact on environmental sustainability due to the way we produce and consume electronics. Only in Mexico, 1220 KT of e-waste is generated annually, and just 3% of electronic waste is correctly disposed of.

Recently, the circular economy has emerged as a worldwide sustainable economic strategy. At its core, a circular economy model intends to design out waste. Products should be designed to last and optimized for a cycle of disassembly and reuse that will make it easier to handle and transform or renew them.

This case study will shed some light on circular steps toward manufacturing electronic devices. From eco-design to a sustainable choice of materials and the importance of considering the post-consumer stage, this case investigates a circular future for electronics.

Sustainable Development Goals Chart

Main Highlights

Problem

- Digital transformation is directly linked to economic growth and impacts environmental sustainability due to the use of toxic substances. Annually, 1220 KT of e-waste is generated in Mexico, and just 3% of electronic waste is correctly disposed of.

- E-waste is a very challenging type of waste. In the U.S, it represents only 2% of the waste present in landfills, but it is responsible for 70% of the toxic substances found in landfills.

Context

- The European Commission’s Circular Economy Action Plan identifies electronics as one of the critical value chains for the transition toward a Circular Economy.

- Worldwide, only 20% of electronics are recycled properly.

Solution

- Designing electronics in a Circular way can balance the increasing demand for electronics with the planetary limits.

- In México, one start-up has begun to design electronics with a circular approach that the electronic manufacturing industry could replicate.

Impact statement

- The global consumption of electronics is forecast to double by 2050.

Systems perspective

- Circularity is only one of the many factors that a company must tackle to become genuinely sustainable. Other challenges like social responsibility and human rights are often disregarded when implementing a circular economy plan, but they must also be at the core of a sustainability action plan.

Case Overview

How could circular manufacturing look for EEE?

First of all, to see what circular manufacturing for EEE looks like, it is necessary to understand its value chain or supply chain – this is an essential step for any process of circular design process.

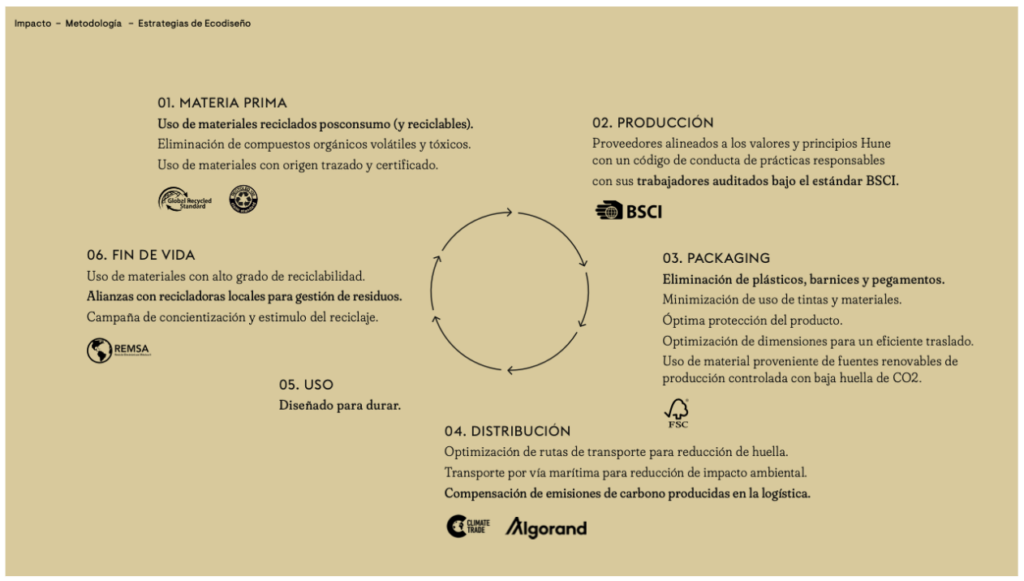

Generally, the value chain or supply chain of EEE manufacturing is

- Resource extraction

- Production

- Packaging

- Distribution

- Use

- End of life

In each of the steps above lies one or several challenges and opportunities for circularity. For instance, the linear economy has always extracted finite resources: could the production of EEE be made using non-virgin raw materials? Production of EEE is often outsourced for economic reasons: could the production guarantee that suppliers work under a code of conduct and responsible practices under the BSCI standard?

Drawing a circular guide on EEE manufacturing

Step 1

Be aware of the three main principles of the Circular Economy

Figure: Circular Economy 3 main principles. Extracted from the Learning Hub of the EMF

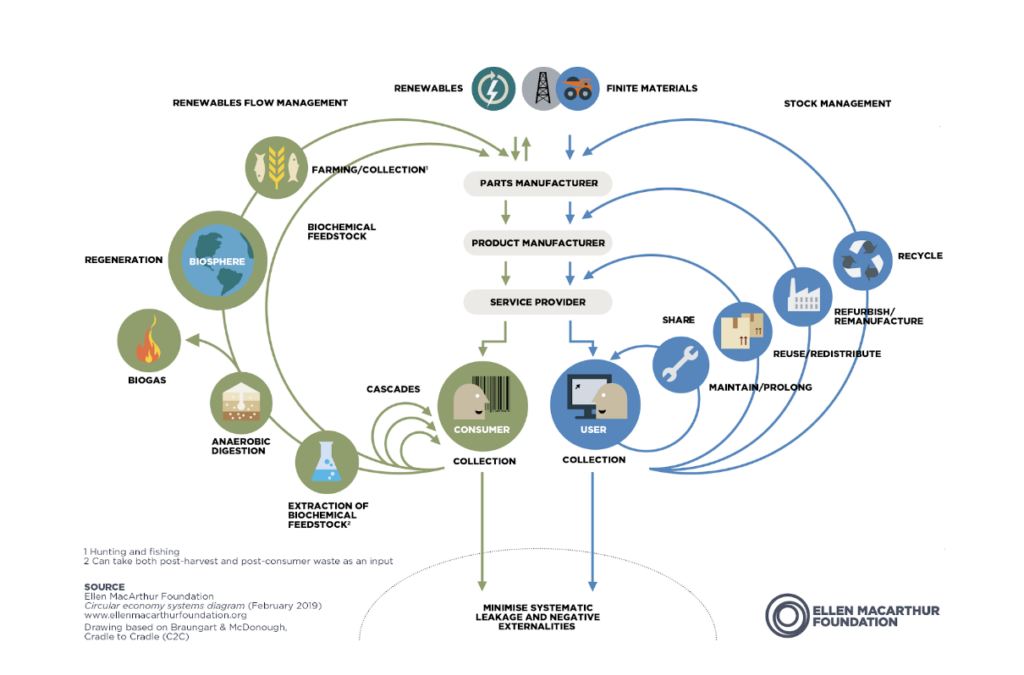

At its core, a circular economy model has three main principles:

1) Design out waste and pollution;

2) Keep products and materials in use, and

3) Regenerate natural systems.

A circular economy is based on the idea that there is no such thing as waste. First, products must be eco-designed to avoid waste and pollution in the first place. Second, products and materials should be designed to last; products and materials should be optimized for a cycle of disassembly and reuse that will make it easier to handle and transform or renew them. And finally, the last principle of the CE has to do with powering this production with renewable energy sources while decreasing resource dependency and improving ecosystemic regeneration (through compensation mechanisms, for example). This last principle is crucial for the reduction of Greenhouse Gas Emissions.

When designing and producing electronics, those three principles are applicable. For example, “Hune” is a Mexican electronic start-up that makes speakers, earphones, and cell phone chargers. They were born using Circular Economy´s tools and theories for its electronic manufacturing. Their products are packaged in cardboard and tinted with natural dye (Principle N.1: design out waste). Their products are also made from 100% recycled plastic, and they are also recyclable. Besides, they are built to last. (Principle N.2: Keep products and materials in use). Finally, their production reduces the carbon footprint to 80-96% less CO2 than similar products (Principle N.3: Regenerate natural systems).

Figure: Hune´s infographic shows how their products are made and their social-environmental impact. Source: Hune.

Step 2

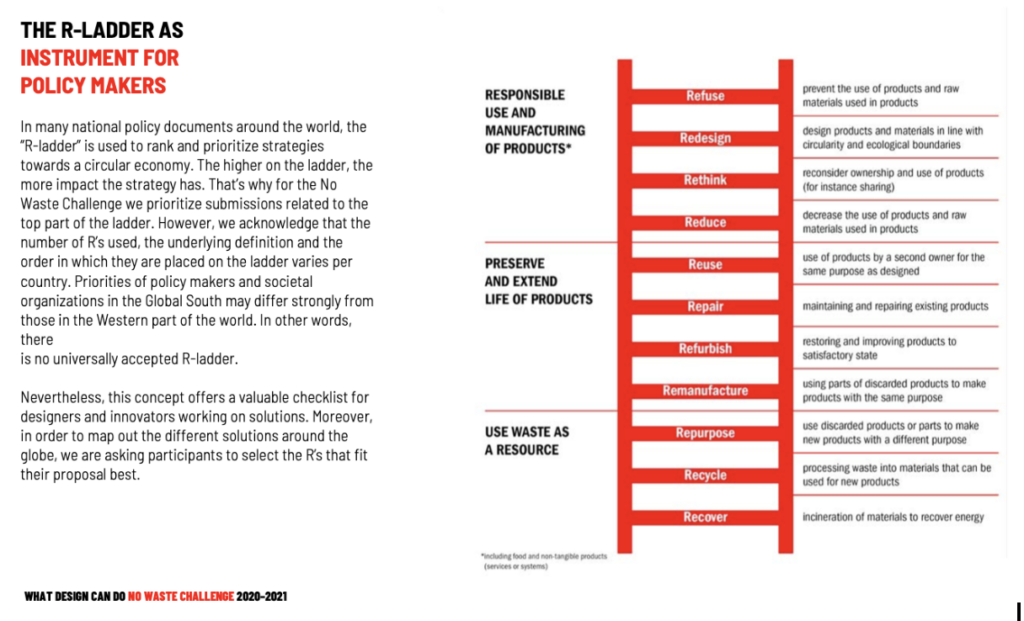

Be aware of the circular economy “ladder”

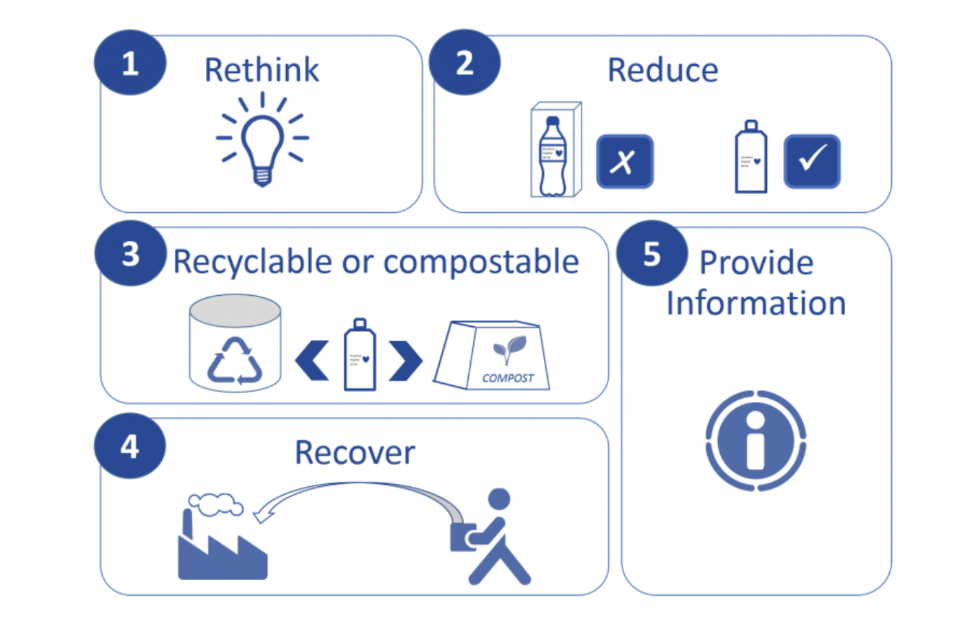

Image: 11 Rs of the Circular Economy. Source: “What design can do”

The Circular Economy ladder was made by What Design Can Do to give some directions towards which actions to take and the priority amongst them. At the top of the ladder, there are priority actions. These priorities are focused on “Responsible use and manufacturing of products.” We must reduce the use of products and raw materials used in products, redesign products and materials in line with circularity, rethink ownership and use (this is often called “shared economy”), and finally reduce the use of products and raw materials used in products. For designers, this ladder provides tools and priorities to make circular products.

In this ladder, recycling is not a priority for the Circular Economy. Therefore its appearance is at the bottom of the ladder. This doesn’t mean we should not recycle; instead, parallel efforts must be taken on the top of the ladders, and at the bottom, without forgetting the priorities.

Step 3

Rethink resource extraction

The linear economy has worked under one dangerous hypothesis: resources are infinite. Yet, the Earth’s overshoot day (when humanity has exhausted nature’s “budget” for the year) is a warning that we are extracting more materials than we can regenerate.

Circular production must rethink resource extraction. Producing with recycled materials is an excellent way to refuse the use of virgin raw materials while simultaneously reducing the carbon footprint of production.

Figure: Hune´s earphones reduce 81% of the carbon footprint by producing using recycled materials.

Step 4

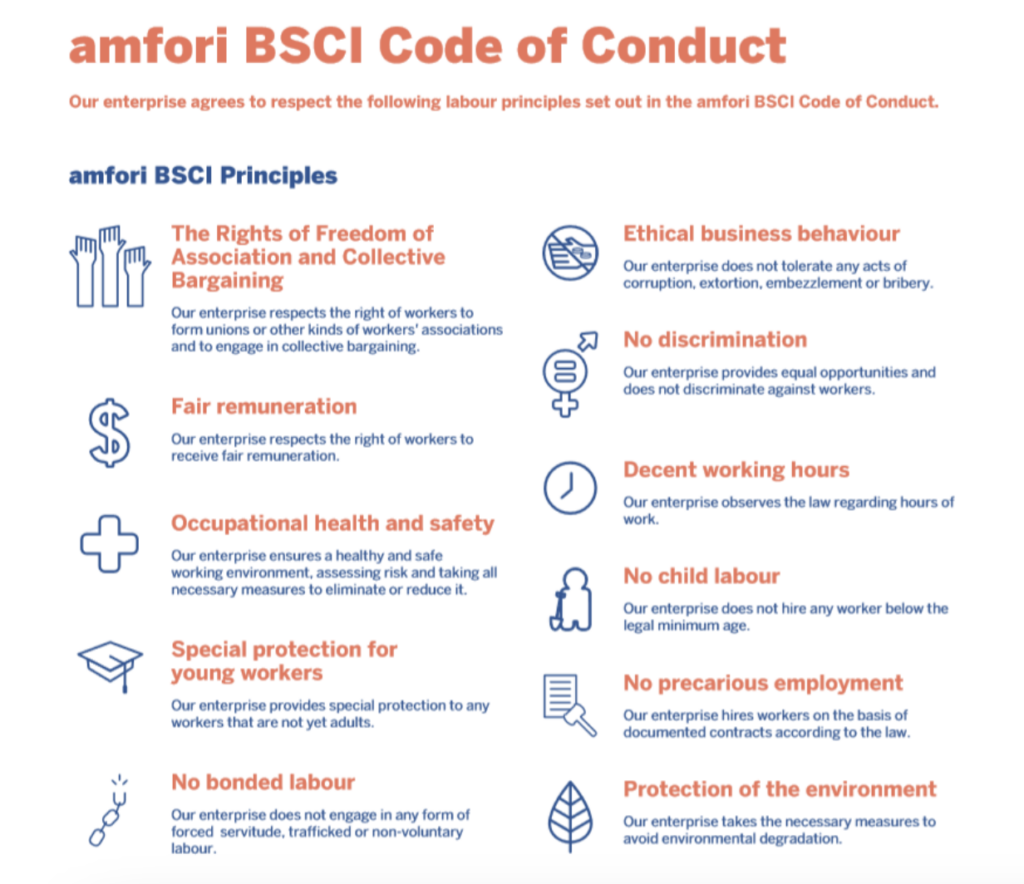

Produce ethically.

The Circular Economy (CE) often disregards human rights and social impact. CE has its core on materials and using materials, but this approach disregards humans.

Production of EEE is often outsourced for economic reasons, and this outsourcing can lead to sustainable social practices.

Guaranteeing social responsibility is also essential when designing for sustainability/circularity. There are many ways to ensure this, but one could be to apply for the BSCI standard or look for outsourcing that can provide this guarantee.

Amfori / BSCI code of conduct. Extracted from Amfori

Step 5

Redesign packaging

Fundamentally, packaging protects products during the distribution chains. It is a warrant that once in the hands of consumers, the products are usable.

Yet, linear packaging only takes into consideration the product´s safety.

A circular approach towards packaging not only has in mind to protect the product but also the planetary limits and the efficient use of resources. Some guidelines to redesign packaging are:

- Rethink packaging

- Redesign and improve volumes and sizes and minimize materials

- Avoid unnecessary plastics

- Deciding if it is going to be recyclable or compostable

- Making efforts toward material and packaging recovery

- Providing clear information on the materials and the way must manage them. For example, there is a big difference between “Home Compost” and “Industrial Compost”; that difference should be clear.

Figure: 5 things to consider on a circular economy packaging checklist. Source: Kogan Page

Step 7

Make it durable, reparable, and recyclable

The circular economy aims to circulate products and materials at their highest value. This means keeping materials in use, either as a product or, when they can no longer be used, as components or raw materials. This way, nothing becomes waste, and the intrinsic value of products and materials is retained.

There are several ways to keep products and materials in circulation, and at this point, it is helpful to think about two fundamental cycles – the technical cycle and the biological cycle. In the technical cycle, products are reused, repaired, remanufactured, and recycled. In the biological cycle, biodegradable materials are returned to the earth through composting and anaerobic digestion.

Figure: Circular economy butterfly diagram. Source: Ellen Macarthur Foundation

Step 8

Always consider the end of life.

When designing for circularity, thinking about what happens after use is crucial. No country has a 100% ideal infrastructure to facilitate recycling processes or reverse logistics.

The private sector must then work towards higher rates of material recovery. Collecting E-waste is very challenging, and not having a circular treatment for them could be potentially lethal. In the U.S, it represents only 2% of the waste present in landfills, but it is responsible for 70% of the toxic substances found in them.

Examples of post-consumer strategies for collection

- Give a discount for new products if users take their old products to the companies collection structure

- Renting instead of selling. Recently, Apple has begun renting their phones instead of selling them. This strategy simplifies the collection, as users must give their used phones to receive a new one.

- Helping the government provide EEE recycling infrastructure.

- Make annual campaigns of EEE collection

Figure: Hune´s strategy is to propose a free pick-up for their products (E-waste) and offers a discount for new purchases.

Impact Statement

Circular Economy´s potential for electronics

Electrical and electronic equipment (EEE) is essential to our lives. Products and services provided by EEE have benefited almost all fields of work in our current society: the services of EEE engineers are required in the field of robotics, transport, healthcare, construction, and many more.

However, how we produce and consume EEE leaves many negative externalities. These electronics are often built using toxic chemical materials and substances lethal to ecosystems. If EEE is not recycled or treated correctly, it can release toxic substances. According to DoSomething.org, electronic waste only accounts for 2 percent of the waste in our landfills, but it is responsible for 70 percent of the total toxic waste.

Moreover, the Global E-waste monitor 2020 shows that most e-waste was generated in Asia, the Americas, and Europe. Europe is also the continent with the highest documented formal e-waste collection and recycling rate (42.5%), followed by Asia (only 11.7%) and the Americas (only 9.4%).

Figure: Global e-waste statistics. Extracted from the Global E-waste monitor 2020

“Statistics can vary substantially across different regions as the consumption and disposal behavior depends on several factors (e.g., income level, policy in place, the structure of the waste management system, etc.)”. The e-waste generated worldwide is generally collected and managed in four ways: 1) Formal collection; 2) E-waste collected in waste bins; 3) E-waste collected outside formal systems (private companies initiatives) and 4) E-waste collected by individuals outside formal systems.

Moreover, beyond e-waste collection and formal disposal systems, it is urgent to redesign EEE following Circular Economy´s tools and theories. These could help design out waste from the beginning. Only in Mexico 1220 KT of E-waste is generated annually. Of these, only 3% get collected and recycled. The private sector must then work towards higher rates of material recovery.

Not having circular strategies is very harmful: in the U.S, it represents only 2% of the waste present in landfills, but it is responsible for 70% of the toxic substances found in them.

Figure: E-waste generation in México in 2014. Source: Hune

Systems Perspective

The alignment of the 3 Circular Economy Principles shows that we can no longer focus on doing less harm to the environment but on how we can actively improve it. If the economy follows circular principles, the more we do, the greater the benefits

Figure: Hune´s supply chain. Extracted from their website.

Links and Contact Information

This section only contains the company website, founders’ LinkedIn profile/s, and contact information if available. The bio of the company is not needed as that should be covered in the case overview.

https://www.vttresearch.com/en/news-and-ideas/five-ways-towards-sustainable-electronics

Case by: 4Revs Researcher Christopher Brosse | October 2022