Main Theme

Sub-theme: Producción responsable, Diseño sostenible, Ecodiseño, Diseño regenerativo, Diseño biofílico, Economía circular.

Abstract

Designing in sustainable materials is a core component for shifting out of default, destructive resource use, to sustainable and regenerative materials use. All companies use design to create their products, but not all companies have a materials expert that can lead their product development . In-house development can be costly, time-intensive, and out of the realm of expertise.

Material Connection (MCX) is a firm that specializes in the latest understanding of global materials. MCX is a one-stop shop where companies can ask any questions pertaining to materials . The MCX Materials Database is a materials library curated with over 10,000 material innovations from over 7,000 global manufacturers. What are the latest alternative leathers? What types of bioplastics are available? What will it cost to shift the production into this new material? What circular materials options do I have for this product’s production in Japan? These are the kinds of challenges that companies can pose to the experts at MCX.

MCX works with global top brands to bring companies closer to their sustainability and circular economy goals. Their materials acumen allows their clients access to the latest in materials science, sourcing, and application. With MCX, sustainable material is no longer guesswork.

Sustainable Development Goals Chart

Main Highlights

Problem: With a global marketplace of thousands of materials to use for production, it is challenging to know which materials are appropriate for sustainability goals. Are they affordable? Are they aesthetically pleasing? What is their production process? Most companies do not have in-house experts to make these crucial decisions.

Context: The global footprint of the materials we use is one of the key determinants of sustainability on the planet. The global footprint network estimates that currently we consume the resource equivalent of 1.75 earths. The only other living organisms that consume their hosts are cancers and parasites. In this case, chimpanzees and gorillas are much better aware of living within the means of the environment than humans. Human exceptionalism has allowed us to consume without considering the web of life we live in.

Solution: A global research hub and Materials library for curating the most appropriate materials for company production.

Impact Statement: Material Connection maintains a Materials Database, with over 10,000 material innovations from over 7,000 global manufacturers. They are the go-to global source on sourcing materials for production.

Case Overview

This year, the globe reaches ‘Earth Overshoot Day’ on July 28th. This is the day when human resource demands exceed the capacity of the earth to sustain. This means that humans have designed systems to take, but not systems to regenerate; that humans have the willingness to manipulate nature for the sake of profit, but not for the sake of stewarding life systems. “We are ploughing through this planet’s finite resources as if there is no tomorrow, causing climate change and biodiversity loss along the way,” reports the International Institute for Sustainable Development (IISD). Modern industrial processes – the machine- has been designed to work apart from nature, and not with nature. Thus, we have designers that do not consider the ecological consequences of the materials that they choose in design.

The materials we use are a reflection of human ingenuity, as well as fashion, culture, and trends. The Bronze Age is named as such, for instance, because of human’s new ability to manipulate this material. Some scholars now call this age the ‘Plasticene,’ due to the global overproduction and use of plastics. Due to the realization of the unsustainability of current materials use, more and more discussions are taking place regarding sustainable materials, transition to a circular economy, eco design, biophilic design, regenerative design, and similar themes.

Material Connection has the motto, “You need reliable, easy-to-understand material information from a trusted source.” Materials Connection is a materials library, materials research, materials consulting, and one’s own materials expert, they are a go-to source for understanding the latest on materials to use across the production sector. They are not daunted by a company’s difficult materials challenges, in fact, they ask for it!

The four points they emphasize for the right material choice are: performance, aesthetic, budget, and sustainability.They see the design component of every project as crucial, and that every project has a range of potential material solutions, but not all are ultimately the right option. Not all companies have the time or budget to have their own in-house materials R&D, not to mention cover the wide range of materials possible, and with this in mind, this is how the Connection can help its clients rise above the rest. They are based in New York City, and have been operational for over 20 years, working with some of the world‘s top brands such as Nike, Google, BMW, Johnson & Johnson, LG, Louis Vuitton, and more. Although based in the US, their materials insights are global.

Materials Connection addresses the issue of sourcing of material:

- How will this material work within our current production process?

- Which materials are best to address our sustainability goals?

- There is so much conflicting information out there, how do I know the information I’ve been given is credible?

Material Connection stands out as they actively track more than 75 industries to provide cross-industry perspective on materials, trends, design, and sustainability. They have their own researchers that they’ll attach to your project. Benefits of their acumen include access to their Materials Database, with over 10,000 material innovations from over 7,000 global manufacturers. Their international research team includes global offices and partners in Japan, Sweden, Denmark, Italy, Spain, Thailand, and South Korea; and additional satellite offices in Denmark, the US and Hungary.

Members of the MCX platform also have additional perks like regular updates on the latest materials and materials science. “Don’t Waste It, Wear It: Food Waste-Derived Leather Alternatives;” “Material Insight: Bacteria Dyed Textiles;” “5 Materials You Need to Know;” “What’s the Difference: Antimicrobial, Antibacterial, and Antiviral?;” and monthly materials trend reports are recent insight profiles that members can access.

Case Studies

In one example, a global luxury brand approached MCX with the request specifically for circular economy materials to be used for luxury boats, playgrounds, and industrial facilities. Their suggestions from their materials search was so highly regarded, that the company retained MCX as a sustainable advisory for the brand. [company name withheld BY MCX for client confidentiality].

Material Connection focuses on the latest, global materials insights. In this feature, they discuss Bio-Pura, a new material innovation of bioplastics made from discarded olive pits – an example of a circular economy where no material goes to waste. Such an application would be good for packaging in places like Greece or other high-volume olive producing and consuming countries.

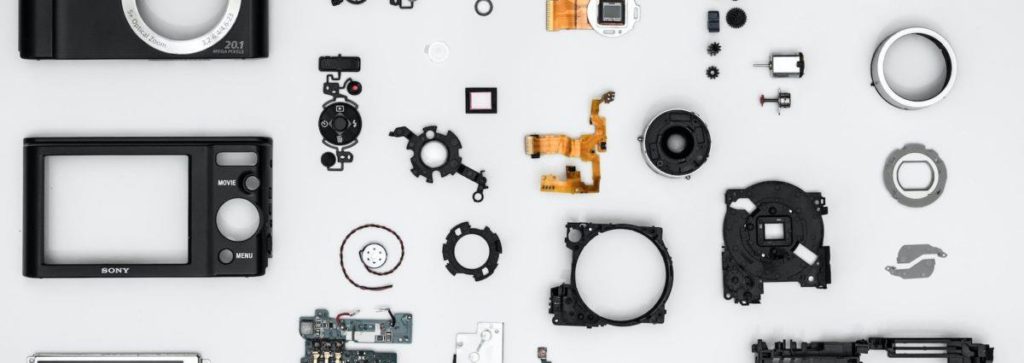

Design for Disassembly: Planned obsolescence is a design plan that is destroying the planet. Designing for disassembly is a design technique that can allow for longer materials lifecycles and circular lifecycles, as well as minimizing waste to landfill, and front-end materials extraction processes.

Featured Material: Bioglitz is a company that realises the need to party, but to do it responsibly! Conventional glitter is plastic, which spreads microplastics extensively when used. This bioglitter is made out of a eucalyptus derivative, but maintains the aesthetic of glitter.

To be a global materials insight leader, MCX follows the trends across 75 different sectors about how materials are being used. The human relationship with paper continues to evolve, and more companies are requiring paper without plastic liners over concerns for recyclability.

Structural Color: Other material focuses are on innovation, but they might not necessarily all be sustainable. Many dyes and colors are chemically derived, which hold industries back in terms of sustainability goals. Playing with structure to generate appealing colors – rather than dyeing – could be one sustainable alternative. This is the forefront of materials innovation.

Impact Statement

Material resource extraction and use is a major contributor to biodiversity loss, land systems change, climate change, and chemical loads on the planet. With mindful shifts to sustainable and regenerative materials , we can change the trajectory of earth’s systems degradation. How we live, what we produce, how businesses operate, is ultimately a choice.

The materials awareness stewarded by Material Connection touches on multiple SDGs:

#1 No Poverty: when materials are sourced responsibly from economically disadvantaged areas.

#3 Good health and Well-being: when materials are not made from toxic chemicals.

#6 Clean Water & Sanitation: responsible materials use starts in the production, and processes that do not damage the watersheds in their extraction or production.

#9 Industry Innovation & Infrastructure: responsible materials are a product of industry innovation, and create new infrastructure pathways and potentialities when new materials are sourced.

#11 Sustainable Cities & Communities: the material we use ultimately determines the sustainability of our built environment.

#12 Responsible Consumption & Production

#13 Climate Action: certain materials have less of a climate footprint than others. This is also geographically determined (i.e. banana fibre might have less of a footprint where it is grown, but a considerable transportation carbon impact if shipped around the globe).

#15 Life on Land: the more we responsibly and sustainably extract and use materials, the less of an impact we will have on biodiversity loss and land systems change – all the other species depend on humans to figure out a more regenerative way to live on the earth!

#17 Partnership for the Goals: Reuse is a cross-disciplinary endeavour, it requires businesses, the civic sector, policy making, all to work collaboratively to create more systems and cultural-shifts for reuse.

Systems Perspective

When we think of the triple bottom line -people, planet, profit – too often the later is prioritized at the expense of the social and environmental. The result of this has been the current destruction that we now see on the planet. Although many companies pay lip-service to sustainability, often when trade-offs between profitability and a more sustainable option are presented, if the price point for a sustainable material is higher, companies opt for the cheaper material. Currently, one of the cheapest materials on the planet is plastic, because it is a byproduct of oil and gas production (meaning that as long as we have continued oil and gas extraction, that will be coupled with virtually free plastic).

The many derivatives of plastic on the market are fundamentally disastrous for the planet, and we can say that virtually all sectors are dependent on plastic at this point. Seventy years ago, this was not the case, but now plastic has been opted for as the default, material of choice. It is going to require a massive global, industrial shift to get companies to opt-out of plastic once again, now that most production systems are tied to this material. Polyester in fast-fashion; LDPE, HPDE, and PET in food packaging; plastic #7 in many hard durable plastics in electronics, automotive, etc., these will be the challenges for production cycles to overcome.

With our current materials crisis, a company like Material Connection can help fill the gap between R&D and the companies that have the capital to experiment with materials shifts. Industry leaders are the ones that need to set the stage for the transition; this is the scale at which material change happens. Imagine if, overnight, Nike decided to phase out plastic use in its apparel and shoes. This would have a groundbreaking impact on global materials demands. It would set the stage and set the bar for an entire industry shift. But alternatives to plastic require the support from larger corporations to fund this research and this scaling up. Essentially, the problem of unsustainable consumptive practices lies within reach of the companies that create it in the first place. For businesses in the global south, access to the MCX could be a challenge. Open sourcing some of this material knowledge – if not all- will be key to sustainable global shifts.

A systems perspective on materials sustainability also requires an understanding of the infrastructure for reprocessing of materials by location. Although MCX specialises in all the front-end research on material potentialities, it does not appear that they focus on the post-consumer reality of where materials end up. For instance, many places in the world do not even have basic recycling infrastructure, so even if a material is ‘recyclable’ it is not actually recycled because there are no facilities to do so. Without regulation and production oversight, many companies get away with packaging materials that are ‘recyclable’ but not recycled.

The creation of new material like bioplastics also creates a grey area where the material needs to be understood through further caveats. Almost all bioplastics need industrial compost facilities. Most people assume that compostable means ‘backyard composting,’ but most bioplastics are molecularly composed like plastics, and require intense heat to break down.

Emergent materials like composites also have several caveats. For instance, wood composite may be made using a byproduct of the lumber industry, claiming it is a product of circular economy. However, after use this material cannot be repurposed or recovered – because the bio composite is mixed with plastics, this material cannot be taken back into its original parts, and thus cannot be recycled or biodegrade. So, ultimately after all, this material will still end up in the landfill.

Composite material: Many experiments with composite materials such as wood, banana, grain stalks find their way into the market, but are these materials truly sustainable? Are some materials merely stalling the landfill process for one more cycle rather than infinitely?

Links and Contact Information

- Biophilic Design: https://living-future.org/biophilic-design/

- Dawn of the Plasticene Age: https://www.sciencedirect.com/science/article/abs/pii/S0262407915602159

- Global Footprint Network: https://www.footprintnetwork.org

- Material Connection website: https://materialconnexion.com

- Planned Obsolescence: https://www.sierraclub.org/sierra/2021-4-fall/material-world/built-not-last-how-overcome-planned-obsolescence

Article by: Dr. Katie Conlon, North America 4Revs Program Manager | June 2022