Abstract

Land-use conflicts; devastating environmental and climatic impacts; and dwindling natural resources/fossil fuels (despite growing demands for energy by global consumers) are forcing power providers to explore and reevaluate sources of energy. Renewable energy sources such as hydroelectric, wave, and wind power -as a product of variable natural processes- are often challenged by inconsistent energy production, high costs, and limited capacities. Yet, an innovative spin on traditional solar energy presents a promising, low-cost alternative to renewable energy generation that may reduce, or even eliminate, many of the key factors deterring investors from regular use of photovoltaic (PV) arrays.

Floating photovoltaics (FPV) are revolutionizing the solar industry and yield vast growth potential over the next decade. The idea is simple; a once land-based PV system is mounted to floating barges in lakes, ponds, or reservoirs and is either anchored to the base of the waterbody or moored to the shoreline. Relocating the PV arrays to the surface of waterbodies serves to boost PV efficiency, minimize land-use conflicts, and creates a symbiotic relationship with the local aquatic environment while creating cost savings in site preparation, land acquisition, maintenance, and in some cases energy transmission infrastructure.

The FPV systems can be standalone or coupled with existing renewable energy sources (hybrid systems). The most common hybrid FPV is solar- hydroelectric, which has grown from 1 MW in 2007 to 1,314 MW in 2018. This growth is projected to reach 13,000 MW by 2022, globally. A recent study by researchers at the US-DOE assessed the technical potential of hybrid FPV for 379,068 known freshwater hydropower reservoirs around the world assuming a water surface coverage of less than 20%. Their estimates suggest a global power potential between 3.0–7.6 TW, an amount equivalent to 16–40% of the world electricity generated in 2018. These estimates indicate that hybrid FPV could significantly contribute to addressing global energy demands in the coming years.

Main Highlights

Impact: $1.1 Billion dollar boost to the Austin economy and 6,300 local jobs created, involving 100s of local companies

- Systems Perspective: Multi-stakeholder engagement between government, business (of all sizes), academia, community organizations in an international marketplace results in a collaborative approach to a systems problem

- Solution to waste, equity and jobs: sustainable business development that also is a positive response to overarching issues of climate change and equity (reducing landfill material reduces carbon and methane emissions, as well as energy needed to extract further resources)

- Re-envisioning of waste management to resources recovery department

- Business-to-business materials reuse/circularity

- Marketplace that re-values materials (from undervalued, overlooked resources, to avenues for business, entrepreneurship and innovation)

- Reduce materials to landfill; reduce footprint of materials used

- Fostering restorative and regenerative economy

Case Overview

The Materials Marketplace is an innovative, collaborative approach to reducing Austin’s waste stream and carbon footprint; as well as creating jobs, and stewarding a burgeoning circular economy sector in the greater Austin region. Through their embrace of the concept of circularity, the City of Austin aims to be the most vibrant hub of circular economy in the United States. The materials Marketplace is a collaborative platform that takes a systems approach to resource wasting challenges, linking businesses of all sizes, the government sector, academia, civic organizations, and works at both the local and international level to recover material that was once headed for landfill. This model allows for “materials matching” or basically pairing wants and needs between one company’s waste stream and another’s production line, closing the loop. This model incorporates both micro-level change (i.e. individuals who join fit-it workshops) to meso (small business to business transactions) to macro change (systems approach for waste flows of great Austin region, across the US, and even globally).

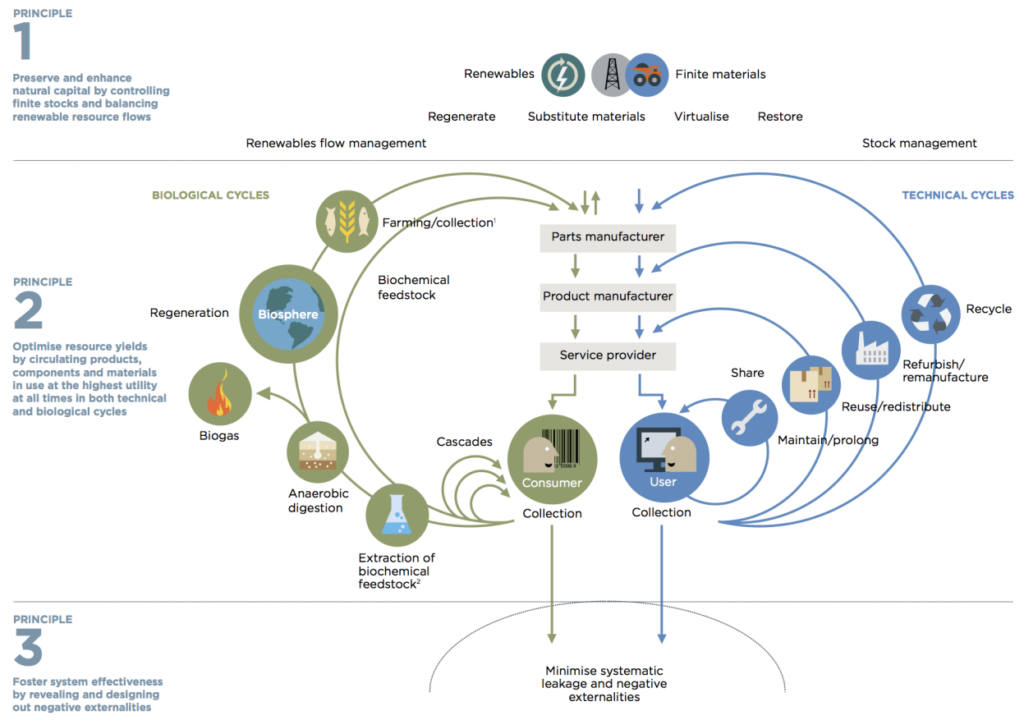

The basis of the circular framework is to design out waste, as elaborated in the foundational book Cradle to Cradle by McDonough and Braungart (2002). Instead of the linear take-make- waste model, circular designs keep materials within the economy and out of the waste stream. In this re-designed system, materials are classified as consumable or a durable product; consumables are mostly organic and easily returned to the environment and durables are human made out of materials like metal, glass, wood, plastic etc., and should be designed from the start for reuse. In principal materials should be non-toxic. Circular business models, for instance, include renting; circular design; keeping materials in use for longer; reuse/redistribution; and recycling. ILSR in the US calculates that for every 10,000tons of waste sent to landfill approximately one job is created; for composting it’s approximately 4 jobs; for recycling it’s around 10 jobs; for the repair economy it is around 100 jobs.

Sustainable resource use is a critical challenge for the globe, and especially the US. Human consumption footprints in the global north continue to rise and create unsustainable ecological deficits. The US, for instance, has the biocapacity per person of 3.4gha (global hectare); on average per person Americans consume 8gha; leaving a biocapacity deficit of -4.6gha (which connects to the phrase, ‘If everyone consumed like an American, we’d need 4.5 earth’s to live on.’ Other countries have worse ecological deficits, but the fact that the economy has been geared around global citizens achieving a US-type lifestyle that makes this pattern worrisome).

How did Austin get started on the path of materials recovery? Three decades ago, Austin invested $40m in an incinerator, and they decided to cancel this plan for waste management, in order to work towards zero waste (Note: incinerating and zero waste are opposite approaches: incineration burns resources, while zero waste attempts to recover and revalue resources). Thus, the City’s commitments towards zero waste allowed them to innovate along the path of resource recovery. The City of Austin’s Resource Recovery Department aims to achieve reducing 90% of the waste sent to landfill by 2040 (the city does not have a Waste Management division, but instead has re-branded the previously-known waste department as the Resource Recovery Department). Although many businesses realize the cost and public image benefits of using recovered material, there are numerous barriers to businesses accessing this material which the Materials Marketplace has tried to resolve, including: lack of access to quality materials; lack of quality controls; lack of supportive policy; lack of reliable sources at scale. The Materials Marketplace program is funded through taxes, and the annual cost of running their small team of a program manager and two staff of is around $260,000 (and a rotation of volunteers). The Marketplace is also linked to a social and economic driver platform called Austin’s Recycling Development Program (also run through the City of Austin), which aims to create zero waste businesses and a zero waste ecosystem in Austin. The Recycling Development Program hosts an e-platform for promoting the businesses that are involved in the recycling, repair, reuse sector; an adjacent project is the Austin [re]Manufacturing Hub.

At the micro level, the Marketplace is host to Fix-it clinics, in which citizens are invited to bring their broken items and learn how to fix them through sewing, soldering, maintenance etc. (fixing as a process that counters planned obsolescence and landfill waste accumulation). Also, the household level includes rebates for home composting and chicken rearing (composting), which keep materials out of landfill.

One of many collaborative offshoots of the Marketplace, at the Meso level the [RE]verse pitch competition aims to reduce waste-to-landfill in Austin, Texas with innovative business approaches in partnership with the city of Austin and the Center for Entrepreneurship at the University of Texas. The competition works by coordinating with local companies that have large materials streams that are going to waste. The concept is like a reverse elevator pitch, instead of innovators selling their idea, they come up with ideas for the company to recover/recycle/upcycle the materials in their waste stream. The City of Austin awards the prizes for the best circular innovation pitch. Previous prizes have been awarded for use of organic waste, vinyl, and other materials that were thought to be ‘difficult’ to recover/recycle/upcycle – which set a precedent for recovery across the city. At the meso level, the Marketplace partners with the University of Texas to counter large amount of recoverable material that otherwise goes to waste when students move in and out.

At the Macro level, Partner institutes with aligning missions to curb waste also include: REMADE Institute (Reducing, EMbodied, energy, And Decreasing, Emissions), a division of the Sustainable Manufacturing Innovation Alliance Corps; ReFED, which is a national nonprofit that focuses on macro-level food waste; the U.S. Chamber of Commerce, which has created a number of Circular Economy case studies and tools; and the Materials Marketplace in other regions, such as Michigan, Ontario, and even Turkey. The Marketplace is intertwined with the US Business Council for Sustainable Development (US BCSD), which has over 20 years of working on sustainable materials management with the business community, and has a diverse network that they have been able to harness for the further success of the Marketplace.

Another highlight of the materials marketplace collaboration at the Macro level is the coordination with UL. UL is a third party agency that can certify: recycled content; estimated recyclability rate of products; zero waste to landfill certification; and a company’s commitments to circularity. Through their ‘Circularity Facts’ program, UL calculates a company’s overall circularity rating. UL also highlights sustainable products on their SPOT Product Database (currently features over 100,000 products).

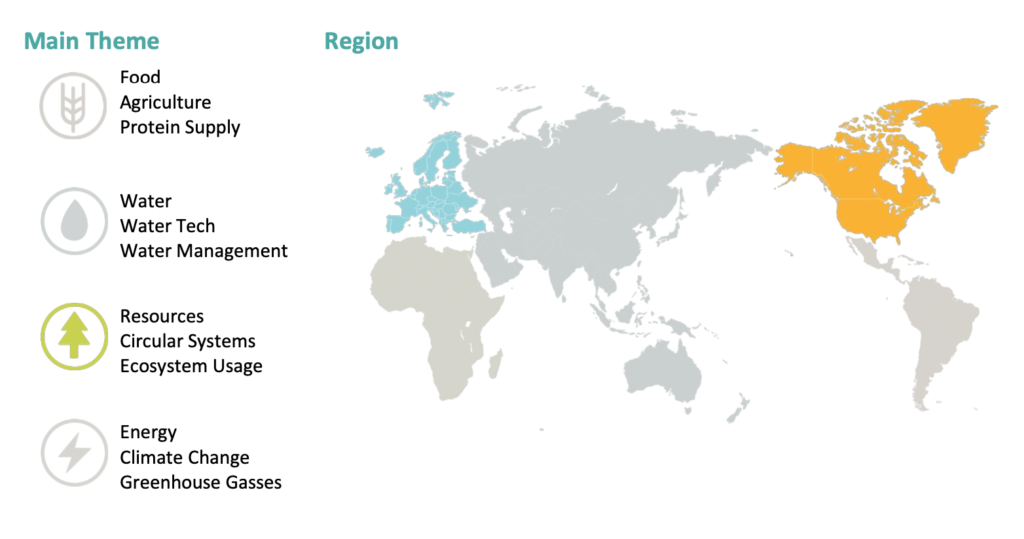

Also at the Macro level, the Marketplace aligns with the vision of key global circularity stakeholders such as the World Economic Forum, which promotes the ‘proven concept’ of moving from linear to circular systems; and the Ellen MacArthur Foundation, dedicated to the acceleration of the Circular Economy through rethinking and redesigning how the world currently does business. Moreover, the Marketplace’s resource exchange is in line with the World Wildlife Fund’s Cascading Materials Vision, which aims to, “help businesses source secondary materials that protect their profits, the environment and future wealth of our natural resources.”

Impact Statement

From the organic beginning of the scrapping of a waste incineration plan, the city of Austin has been able to re-envision its entire materials flow system from the ground up. Through the Materials Marketplace, the Austin region has shifted wholly from waste management to resource recovery. That the city has taken a systematic approach to the waste problem, has allowed a wide-range of stakeholders to participate and this diversity has enabled this programs success; as well as garnered the attention that has created spin-off models in other cities across North America as well as globally.

Indicative of its systematic nature, the program hits numerous SDGs including:

- SDG #8: Decent work and economic growth (through $1.1 Billion USD added to the local economy, as well as approximately 6,300 jobs);

- SDG #9: Industry, innovation and infrastructure (through the innovation challenges; the new industry created through the materials exchange; the superstructure of the marketplace)

- SDG #10: Reduced inequalities (through inclusionary job creation)

- SDG #11: Sustainable cities and communities (through addressing the problem of increasing waste streams, and waste to landfill)

- SDG #12: Responsible consumption and production (through closing the loop with circular economy)

- SDG #13: Climate action (though reducing emissions from landfills; reducing the use/extraction of raw materials; localizing the economy to reduce transportation miles) · SDG #15: Life on land (less land degradation through landfilling; less resource depletion through reuse/recovery)

- SDG #17: Partnerships for the goals (regional, inter-regional, and international partnerships to reduce waste and recover materials)

Systems Perspective

Although circularity is an optimal model for resource valuation and keeping material out of landfills; it can also reduce pressures on companies that create excess and undesirable waste streams. Materials like glass and aluminum are infinitely recyclable, and do not contain chemicals that leach into the environment. Other materials like e-waste, plastics, industrial waste, lubricants and chemicals ultimately can create more cycles of harm if recirculated. As a society, we have the technological skills to do almost anything with materials – coprocess hazardous chemicals in the burning of cement kilns; mixing e-waste into tiles; turning plastics into fuels, for example – but we seldom ask the question IF we should be producing such waste to begin with, and are such solutions to hazardous items to be celebrated? Moreover, all the steps that contribute to the end product of ‘waste’ are the result of cumulative resource use, too often through the use of fossil fuels (transportation and production) that contribute to climate change and high water usage (growth and production) that contributes to water pollution and scarcity. Production of non-organic products also increases toxic and chemical loads on the planet. Thus, reduction of waste before it needs to be recovered is always the cheapest and best answer.

Global narratives on circularity are dominated by organizations like the Ellen MacArthur Foundation, which heavily promotes the circularity of plastics. Step 3 ‘Design out pollution’ and Step 4 ‘Keep products and materials in Use’ in the MacArthur Foundation’s aims for circular economy, run into caveats when considering the latest scientific reports on plastic. Bankrolling plastics within the circularity model is problematic as many of the materials that we use for everyday and household applications are linked to health effects. Industry has been ignoring reports on toxicity, but the scientific community has been making increasing warnings on the toxicity of even the most ‘benign’ plastics like plastic packaging; and link continued, human exposure to plastics to endocrine disruption and global patterns of rapidly, decreasing fertility. Thus, industry is still very enmeshed with plastics and does not seem willing to let this material go without regulation.

In working towards the broader systems-goal of zero waste, having a Materials Marketplace in every city is a necessary step. In the Zero Waste Hierarchy, refuse, rethink and redesign constitute the first category of priority for materials management, and just underneath that is Reuse. Thus, in order to address the first tier, the Marketplace could also be coupled with a materials research center (as described as one of the key steps towards zero waste by Connett in The Zero Waste Solution), which would be an ongoing research hub linked to the University for observing the waste material flows of the city. Researchers would be able to identify flow trends; hazardous flows; policy considerations; link waste to broader social and environmental concerns; and emphasize this first tier of rethinking, redesigning and refusing waste generation. this.

References:

Austin Materials Marketplace https://austinmaterialsmarketplace.org/the-circular-economy

Austin, Texas, Supports Circular Economy with New Incubator

https://www.waste360.com/waste-reduction/austin-texas-supports-circular-economy-new-incubatorAustin Resource Recovery. http://www.austintexas.gov/department/austin-resource-recovery

Circular Cities Week Report.

https://circulareconomy.europa.eu/platform/sites/default/files/ccw_report_2020.pdfCircular Resources for businesses and nonprofits; resources for individuals. City of Austin.

http://austintexas.gov/department/circular-economy-programConnett (2013). The Zero Waste Solution. https://www.chelseagreen.com/product/the-zerowaste-solution/

Ellen MacArthur Foundation. https://www.ellenmacarthurfoundation.org/

Ellen MacArthur Foundation. The Circular Economy in Detail.

https://www.ellenmacarthurfoundation.org/explore/the-circular-economy-in-detailGlobal Footprint Network:

https://data.footprintnetwork.org/?_ga=2.230355292.1397034854.1617611723-1590488950.1617611723#/ISLR. (2021). How Recycling and Reuse Created Thousands of Jobs and a Boost to Austin’s

Economy https://ilsr.org/recycling-austin-episode120/IPEN (2020). Plastic’s additives and the circular economy. https://ipen.org/documents/plasticstoxic-additives-and-circular-economy

McDonough, W., Braungart, M., Cradle to Cradle: Remaking the Way We Make Things, New

York: North Point Press, 2002. https://mcdonough.com/writings/cradle-cradle-remaking-waymake-things/[RE]verse, waste to innovation challenge with the city of Austin and the University of Texas

https://reversepitch.org/Shanna Swan. Countdown. https://www.simonandschuster.com/books/Count-Down/Shanna-HSwan/9781982113667

UL. Circular Facts Program. Verifying and promoting corporate sustainability and circularity

https://www.ul.com/resources/circularity-facts-programUS Business Council for Sustainable Development (US BCSD) https://usbcsd.org/

- John Wackman and Elizabeth Knight . The Repair Revolution: How Fixers are Transforming Our

Throwaway Culture.

https://www.newworldlibrary.com/Books/ProductDetails/tabid/64/SKU/86605/Default.aspx#.Y

GW3eUgzYyk - World Economic Forum. From linear to circular – Accelerating a proven concept

https://reports.weforum.org/toward-the-circular-economy-accelerating-the-scale-up-acrossglobal-supply-chains/from-linear-to-circular-accelerating-a-proven-concept/#view/fn-12 - World Wildlife Fund: Cascading Materials Vision:

https://www.worldwildlife.org/projects/cascading-materials-extending-the-life-of-our-naturalresources#:~:text=The%20Cascading%20Materials%20Vision%20is,wealth%20of%20our%20natural%20resources.&text=But%20WWF%20does%20not%20seek%20to%20impact%20industry%20alone. - Zero Waste Europe, Zero Waste Hierarchy https://zerowasteeurope.eu/2019/05/a-zero-wastehierarchy-for-europe/

Article by:

Katie Conlon: Researcher with Portland State University, National Geographic Explorer, and North America 4Revs Program Manager. I focus on plastic and waste reduction, and generating environmental awareness and connection.

*PM for North America, and researcher for this month’s case